Custom Components

In 2025, J.F. Taylor expanded its capabilities through the acquisition of Bugeye Technologies, a leader in simulation hardware and engineering services. Now operating as Bugeye Technologies Powered by J.F. Taylor, the company continues to offer its own robust portfolio of simulation products and services while contributing to the overall strength and versatility of the J.F. Taylor brand.

Bugeye Technologies Powered by J.F. Taylor is the simulation industry’s first choice for accurate, realistic, serviceable, and affordable hardware. Supporting a wide range of aircraft and vehicle platforms, Bugeye offers a comprehensive selection of Commercial-Off-the-Shelf (COTS) and custom-fabricated products, including:

- Primary flight controls

- Avionics, displays, and panels

- Cockpits, control sticks, throttles, cyclics, collectives, yokes, and rudder pedals

Many of these components are available in multiple levels of fidelity to meet diverse training and simulation needs. From individual switches to fully integrated cockpits, Bugeye’s solutions are engineered for precision and performance.

In addition to its product offerings, Bugeye provides a full suite of engineering and support services, including turnkey development, build-to-print manufacturing, and rapid prototyping for complex simulation systems.

Together, J.F. Taylor and Bugeye Technologies deliver a powerful combination of innovation, reliability, and value—ensuring customers have access to the most effective and efficient solutions in the defense simulation space.

Custom Components & Engineering Solutions

Bugeye Technologies Powered by JF Taylor specializes in the mechanical and electrical design of custom components for flight simulation and training systems. Our expertise includes:

- Flight simulation controls

- Cockpit trainers

- Cable and wire harness assemblies

- Specialty components for military and industrial applications

Our in-house team of mechanical engineers and draftsmen can:

- Customize existing products to meet your specifications

- Build to your print

- Collaborate with you to design entirely new solutions for your unique application or program

To ensure the highest standards, we maintain an IPC-certified cable and wire harness trainer on staff, reinforcing our commitment to quality and precision.

Our Capabilities

Mechanical Design Expertise

From highly detailed individual components to complete training systems comprising tens of thousands of parts, Bugeye Technologies Powered by JF Taylor delivers precision-engineered mechanical solutions tailored to your program's exact requirements. Our team excels at managing complexity—ensuring every part fits, functions, and performs flawlessly within the larger system.

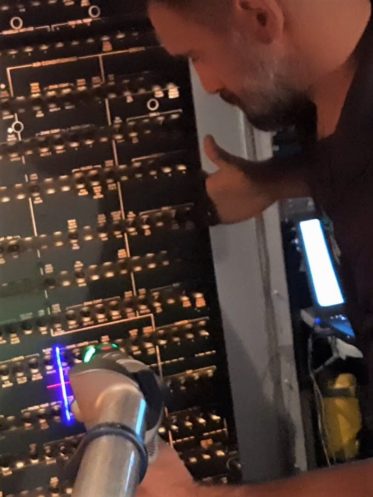

Electrical Design & Integration

Provides comprehensive electrical design services—from detailed schematics to complex electro-mechanical systems including control-loaded motors and drives.

Full-Scale Production Services

Once your product is designed, we can take it from concept to completion. Whether you need a single prototype or a full production run of 10,000 units, we have the facilities, expertise, and quality systems in place to deliver with precision and consistency.

Firmware Development & Interface Design

As a key extension of our design capabilities, Bugeye Technologies offers custom firmware development to support a wide range of system requirements. Our expertise includes:

- Custom I/O requirements and displays

- User-friendly graphical user interfaces (GUIs)

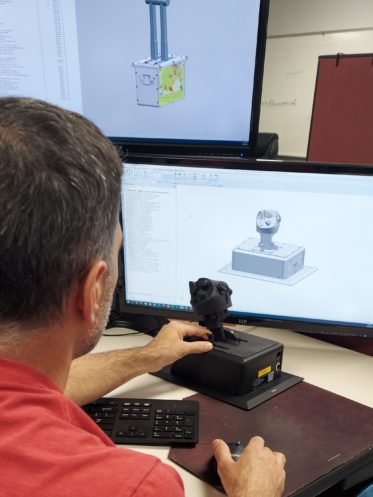

3D Scanning & Reverse Engineering

We offer advanced 3D scanning and reverse engineering services to support the development of highly accurate simulation solutions. We can scan:

- Full cockpits

- Aircraft

- Specialized equipment and components

3D Printing & Rapid Prototyping

We own and operate multiple advanced 3D printers, enabling us to quickly and cost-effectively prototype, test, and refine design concepts.